Wooden Dodecahedron

The finished Dodecahedron

Another angle of the finished Dodecahedron

Laying out initial blocks, and marking out the base pentagons.

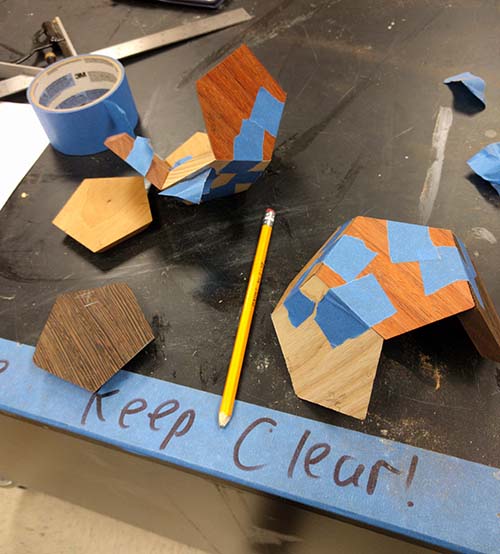

Setting up the two halves of the dodecahedron, laid out to avoid colors touching.

Using painters tape as claps to glue sections together one by one.

Then those sections were glued together to get the final shape.

The Wooden Dodecahedron was an experiment in geometric woodworking to create a 12-sided pentagonal prism as a gift. It was made using a miter saw, band saw and a lot of patience.